Modern Modular Engineering & Construction Company (MMEC) was founded in 2017, began construction phase I in 2019, and commenced fabrication operations in late 2020. As an international supplier of industrial structural steel and modularized solutions, MMEC serves the Energy, Oil & Gas, Chemical Processes, Mining, and Heavy Construction industries.

MMEC operates alongside sister-company Modern Heavy Industries (MDHI) as part of Modern Group, a more extensive, family-owned network of structural steel engineering companies. The owner's goal of MMEC and MDHI was to serve the global community with high-quality products in a world-class setting. To this end, the management caliber, character, project management, transparency, communication, and business ethics has remained the driving force of Modern Group's success.

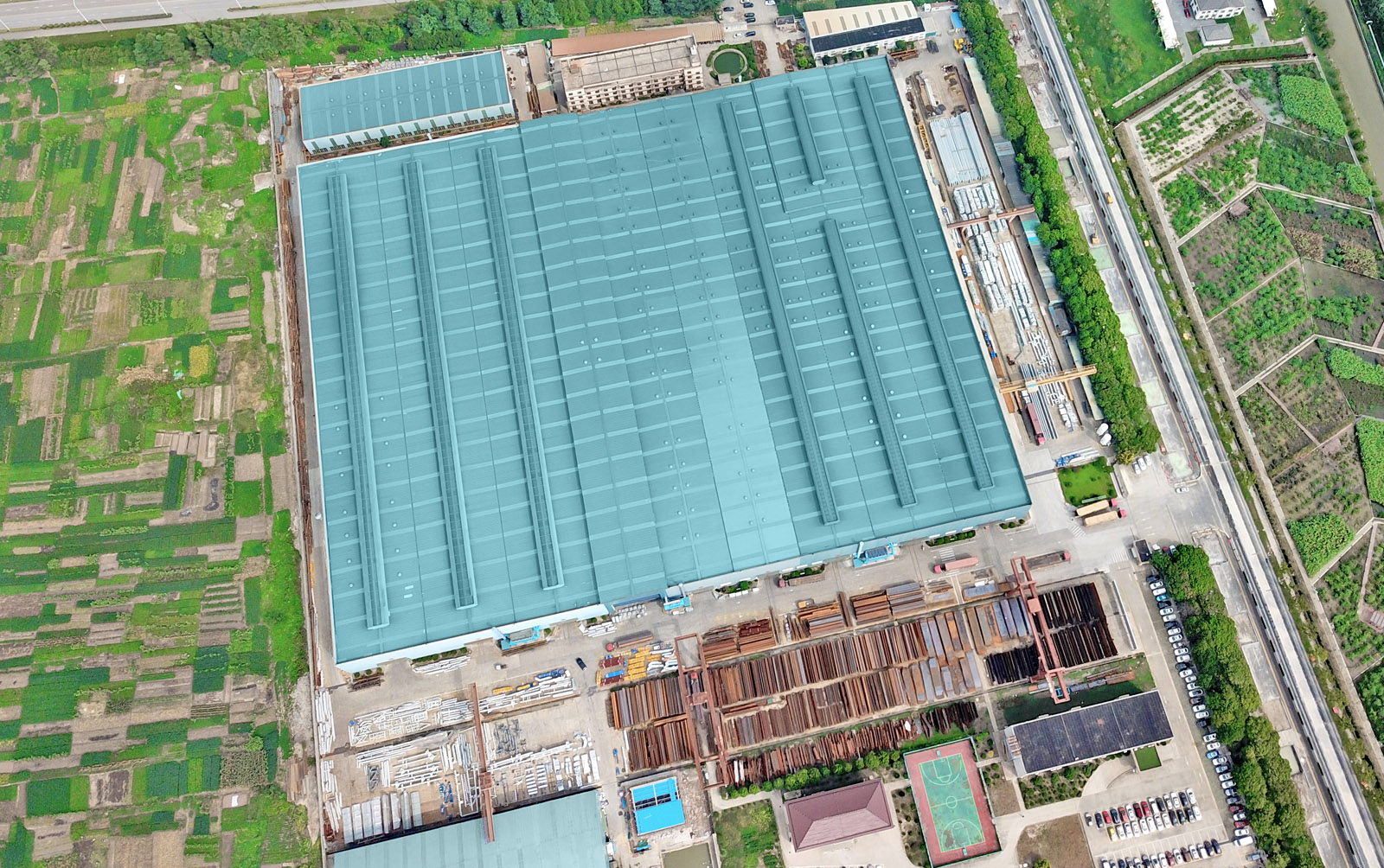

Modern Modular Engineering & Construction (Suzhou), or MMEC, is located in Zhangjiagang, Jiangsu Province, China, 150km northwest of Shanghai, near Changzhou, Wuxi, and Suzhou. (See Map). The location is accessible by air and high-speed rail. MMEC's business focus is steel structures and modular construction for most heavy industries. In addition, the MMEC workshop is adjacent to the Yangtze River Heavy Equipment Port.

Modern Modular Engineering & Construction's Shanghai business office is located at 183 Kaibin Road, Building B, Suite #507, Xuhui District, Shanghai. Office hours are 08:30-17:00, Monday thru Friday.

Modern Heavy Industries (Taicang), MDHI, is located in Taicang City, Jiangsu Province, China, 45km northwest of Shanghai, near Suzhou and Kunshan (See Map). The location is accessible by air and high-speed rail. MDHI's business focus is heavy steel structures for most industries. In addition, the MDHI workshop is 9 kilometers from Taicang Port and 20km from Shanghai Luojing Port.

MMEC supplies fabricated structural steel and piping spools for modules of various industrial applications. Below is a product overview.

- Hot-rolled steel profile fabrication, including H-Beams, channels, angles, schedule Pipe, and hollow steel sections.

- Built-up steel sections, box columns, complex assemblies, heavy girders, trusses, nodes, and jumbo steel sections.

- Carbon steel and stainless-steel piping, duplex & super-duplex, copper-nickel, valves, actuators, instruments, and accessories.

- Architectural elements, facades, mechanical plate work, stacks, vessels, casing, ducts, chutes, hoppers, liners, wear plates.

- Bulk conveyors, transfer stations, gallery, overland truss, pipe racks, offshore dolphins, platforms, access steel, handrails, ladders, and grating.

- Modular process skids, modular pipe racks, pre-assembled units, construction modules, furnace modules, air-cooled heat exchangers, wellhead skids, manifold skids, separation skids, water treatment modules, complex process modules.

MMEC facilities supply large and heavy structures and modules for various global projects.

- Thermal Power Plants - Coal-Fired, Natural Gas-Fired (OCGT, CCGT/HRSG), Biomass, Waste-to-Energy, Biogas, Geothermal.

- Renewable Power Plants - Hydropower Plant Structures, Solar Thermal Plant Structures, Tidal Power Equipment.

- Construction - Sports Stadiums, Arenas, Major Venue, High-Rise Structures, Complex Steel Structures, Theme Park Structures, Typical Buildings.

- Mining Plants - Above and below ground ore and mineral mining plant structures and mining modules.

- Oil & Gas Plants - Well Structures, Tank Structures, Natural Gas Plants, Gathering Stations, and Oil Refineries.

- Chemical & petrochemical plant structures and modularized products.

- Water Treatment Process

Zoom for details.

Zoom for details.

Zoom for details.

Zoom for details.

Zoom for details.

MODERN GROUP SERVICES

Modern Group offers a one-stop solution for many types of industrial projects. For our customers, we provide value-added services that simplify the supply chain, increase efficiency, and result in better quality products and a more enjoyable experience.

PRE-SALES SERVICES

- Prequalification

- Company Media

- Project Review

- Cost Estimating

- Project Scheduling

- Attend Meetings Abroad

- Quality Audits

- Document Samples

- Drawing Samples

- Execution Plan

MANAGEMENT

- Single-Point Management

- 10+ Years Experience

- Excellent Communication

- Transparency

- Fluent in English

- Master Schedule / Planning

- Weekly Production Meetings

- Contract Administration

- Inter-Department Liaison

- Progress Reporting

ENGINEERING

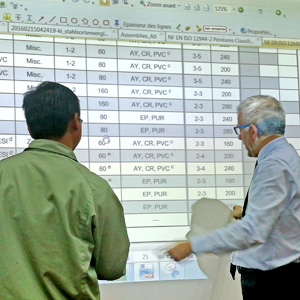

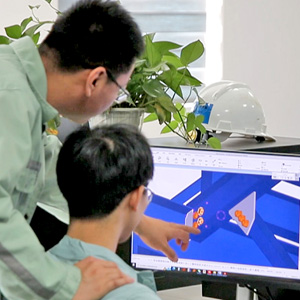

- Drawing & Model Review

- 3D Modeling (BIM)

- Detailed Engineering

- Structural Detailing

- RFI / Change Management

- Clash Checking

- Shop Drawings

- Procurement Lists

- Erection Drawings

- Packing Estimations

QUALITY

- Multi-Certified QC Team

- IWE/CWI - WPS/WPQR

- L-III PT, MT, UT, NASE

- Material Inspections

- Full Material Traceability

- Multi-Certifed Welders

- Mutinational Certifications

- 3rd Party Hosting

- Supplemental Testing

- Methodology & MDR/MDB

PROCUREMENT

- Raw Material Procurement

- Multinational Standards

- Long Products & Piping

- Bolts & Fasteners

- Most Grades & Profiles

- Carbon, Stainless, Exotics

- Welding Consumables

- Protective Coatings

- Free-Issued Materials

- Buyouts & Equipment

FABRICATION

- Primary & Secondary Steel

- Girder & Truss

- Jumbo Steel Sections

- Complex Assemblies

- Support Steel Structures

- Modular Pre-fabrication

- Piping Spools

- Heavy Plate Work

- Bridge Components

- Tanks & Vessels

MODULAR CONSTRUCTION

- Detailed Engineering

- Structure Fabrication

- Piping Prefabrication

- Stick-Built Modules

- Trial Assembly

- Module Erection

- Equipment Installation

- Piping Installation

- E & I

- Coatings / Fireproofing

LOGISTICS

- Packing Lists (PPL/FPL)

- Frieght Volume Estimates

- Global Freight Quotes

- Bulk, RO/RO, Containers

- International Packing

- Heavy Lift & SPMT

- Customs Clearance

- Port Storage

- Fumigation / Washdown

- Vessel Loading

FREQUENTLY ASKED QUESTIONS

PRODUCTION PERCENTAGES

Modern Group includes MMEC and MDHI (Modern Heavy Industries). Together the business units supply projects across several key industries. Below are the historical percentages of contracted manufacturing.

.png)